Read Time: 6 minutes

You already know how stringent the requirements can be to operate a cannabis business. Newer operators, though, are often surprised to learn how quickly small regulatory issues can spiral out of control into major supply chain disruptors; sometimes resulting in the prevention of processing or distributing your product.

California uses the METRC (Marijuana Enforcement, Tracking, Reporting, and Compliance) system to keep track of the movement of cannabis products from seed to sale. It’s a track and trace system that California cannabis operators must update regularly, even when just moving cannabis products within their own company or facility. If you or your employees are not updating the tracking of your goods regularly in METRC, this can result in violations or a complete shutdown of production. Even worse, there is typically a lag between when the issue is occurring in your business and when it may be flagged and inspected by California officials. This means that potential issues can go unchecked and unremediated for several weeks.

Fixing regulatory compliance issues almost always needs to start with employee training. Your cannabis business should have clearly defined processes that your employees are following and documenting closely. Employees need to understand the importance of not cutting corners and adhering to each step. At this point too, it may be worth reassessing if you have the right people assigned to the job.

If you are still struggling to identify where your cannabis supply chain breakdown is occurring when it comes to state regulatory compliance, BeGreenLegal offers a Compliance Analysis, to both support your employees with solid operating procedures and serve in an internal audit capacity to ensure adoption of the procedures.

Supply Chain Issue #2: Improper Vetting of Cannabis Supplier

There is nothing more frustrating in manufacturing or product sales than when a supply chain issue occurs due to something completely outside of your control. In cannabis, this can happen not only based on factors like the availability of supply and regulatory changes, but also because of factors like the operations and quality control procedures of your suppliers. A vendor may have to halt production due to contamination issues with active ingredients, poor packaging or storage, or problems with excipients added to their cannabis products.

The supplier vetting process is tremendously important to identify which supplier not only produces the best product at a fair price, but also takes all required compliance steps to continue operating for many years to come. You can vet your suppliers by:

- Evaluating the supplier’s operational standard operating procedures (SOPs)

- Reviewing the supplier’s compliance and quality management system

- Obtaining copies of the supplier’s certificate of compliance (sometimes called a certificate of conformance) with their packaging

- Obtain current copies of other certifications of analysis or testing

It’s important to note that this is not an exhaustive list of the appropriate due diligence that should be done before contracting with a supplier. If you are unsure of how to incorporate quality control measures around your work with suppliers, BeGreenLegal’s Quality Management System provides recommended actions to protect your cannabis operation and keep product moving.

Which brings us to our next point…

Supply Chain Issue #3: Weak Quality Control Procedures

If there is one thing that sinks more cannabis operations, it’s failure to create and/or adhere to strict quality control procedures. It’s one of those things that every business knows they have to do, but it’s also the easiest area to cut corners when you’re operating at full speed and just trying to keep up with work demands.

We have seen companies let down their guard, only to have their supply chain completely halted by an aspergillus bacteria contamination in their products. Quality control procedures must thread through each step of operations, from the receipt and quarantine of products, to proper cold room storage, processing and handling methods, to packaging inspection.

Each step of your operations should have a documented SOP, with proper logging and tracking at each stage of your process. If you have the sense that your quality management is not up to snuff, do not wait until you have a contamination issue to act. This is the area of your business where being proactive is key. BeGreenLegal’s Compliance Analysis may be one of the most worthwhile investments your business can make.

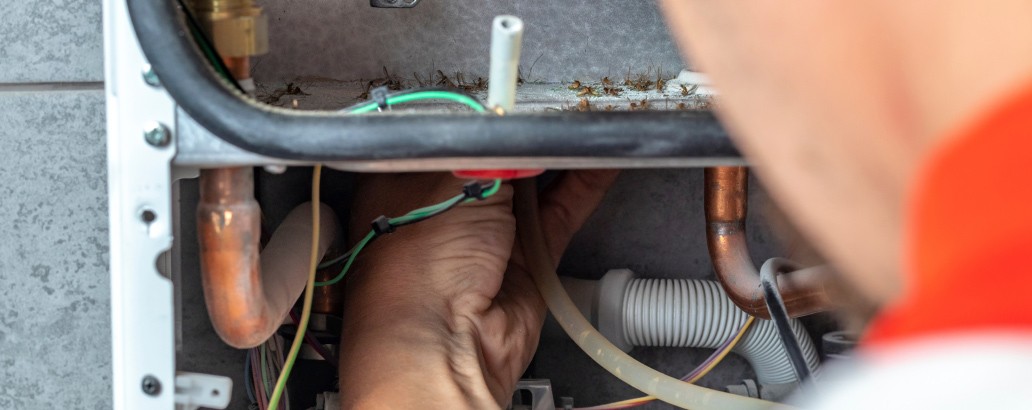

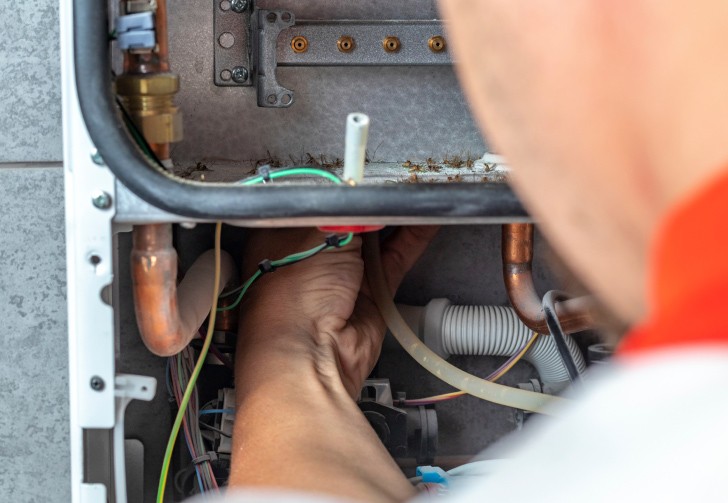

Supply Chain Issue #4: Equipment Malfunctions

It’s not surprising that at some point in your operations, some piece of equipment will fail and need repair or replacement. How you plan for those malfunctions can make all the difference, though, in whether your production can continue moving along.

One of the best and easiest ways to limit equipment malfunctions is to ensure that your team is following the required SOP for the cleaning and maintenance of each machine you use. Not only should the SOP be clear to follow, employees should also receive proper training in the cleaning and maintenance, and all activity should be logged.

It’s impossible to prevent all equipment malfunctions from happening, but having a plan for when they do and being proactive with maintenance will save you from significant supply chain headaches down the road. If your plan needs professional review and consultation, our experts at BeGreenLegal are here to help.

Supply Chain Issue #5: Lack of a Robust Operating System

You may have noticed the common thread through this blog that the best way to keep your cannabis supply chain operating is through proactive planning. As Benjamin Franklin once said, “An ounce of prevention is worth a pound of cure,” and that could not be more true when it comes to the cannabis industry. Doing things right from early on in the process will save you from both headaches and financial hemorrhage.

The most important overarching need of proper supply chain management is the existence of a robust operating system. Gone are the days when tracking on simple spreadsheets was sufficient to manage all of the data requirements for a cannabis business. A robust operating system that is built specifically for cannabis operators not only serves as a place to store and evaluate your business data, it is also the guide that can help keep your operations proactively on track.

Don’t wait for major problems to arise. In an industry where compliance and quality management are key, it’s important that you are prepared for potential supply chain disruptions. BeGreenLegal’s cloud-based operating system was built based on years of experience within the cannabis industry and our knowledge of compliance and quality requirements. It is designed to support you in the most critical areas of your operations.

Ready to be done with your biggest supply chain woes? Contact our team today to learn more about how our cannabis operating system can streamline and standardize your cannabis business.